600DPI Cardboard Digital Printing Machine Wide Format

Product Details:

| Place of Origin: | Suzhou, China |

| Brand Name: | Ge Run |

| Model Number: | WEP-2504AF+ |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | RMB Meet to talk about |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Product Name: | Cardboard Carton Box Digital Wide Format Printing MachineWEP-2504AF+ | No.s Of Print Head: | 4 |

|---|---|---|---|

| Rip Software Rip: | Maintop | Picture Format: | TIFF,JPG,PDF,PNG |

| Print Head: | EPSON Industrial ALL-MEMS Print Head | Max. Printing Width: | 2480mm |

| Media Thickness: | 1-20mm | Max. Printing Speed: | 380m²/h |

| Printingresolution: | ≥360DPI*600DPI | ||

| High Light: | 600DPI Cardboard Digital Printing Machine,Cardboard Digital Printing Machine Wide Format,Cardboard Printing Machine |

||

Product Description

Cardboard Carton Box Digital Wide Format Printing MachineWEP-2504AF+Description

Wide Format

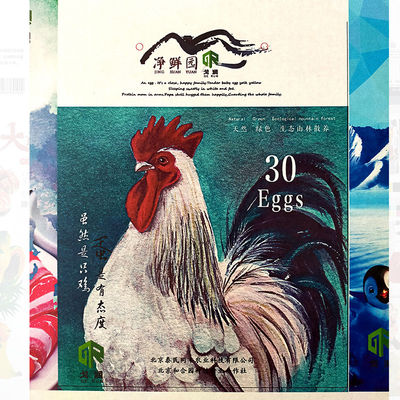

Cardboard carton box wide format printing machine is a printing press designed to print high-quality graphics and text onto large format cardboard boxes. The machine uses advanced printing technology such as flatbed UV-cured inkjet printing to produce high-resolution prints with vivid colors and sharp details.

These machines can accommodate a wide range of carton or box sizes and shapes, making them suitable for printing various packaging designs. They can print on both sides of the cardboard simultaneously, saving time and increasing productivity.

Wide format printing machines for cardboard carton boxes are ideal for businesses that require custom-designed packaging in large quantities, such as e-commerce companies, manufacturers, and distributors. With their high-speed printing capabilities and full-color printing, they can produce high-quality packaging that will stand out on store shelves and provide an attractive, eye-catching appearance for shipments.

WEP+Series Progressive Type Main Features

Intelligent sensor system actualizes automatically feeding, saves cost by reducing manual force. Press roll transimission associated air suction platform makes material flat and stable to guarantee the printing quality.Using Epson micro piezoelectric nozzle to make high quality printing.

Siemens PLC control system, ensure the accuracy of material transfer in the printing process.

Japanese Panasonic high precision servo motor ensure the printer output stable and a longer service life

Dell Industrial computer, anti-interference, printing dada been transfered more smoothly

Japanese Omron photoelectric sensor makes the cardboard positioning more precise and stable transmission.

|

Model |

WEP-2504+ |

|

Rip Software Rip |

Maintop |

|

Picture Format |

TIFF,JPG,PDF,PNG |

|

Print Head |

EPSON Industrial ALL-MEMS Print Head |

|

No.s of Print Head |

4 |

|

Ink type and color |

CMYK Water Based Ink |

|

Max. Printing Width |

2480mm |

|

Media Thickness |

1~20mm |

|

Max. Printing Speed |

380m²/h |

|

Min. Feeding Width |

350mm*450mm without scoring, 350mm*660mm with scoring |

|

Max. Feeding Width |

2500*1500mm |

|

Printingresolution |

≥360DPI*600DPI |

|

Feeding Mode |

Auto feeding |

|

Operating System |

Windows 7 or Later Version |

|

Working Environment |

18~30℃, humidity: 50%~70% |

|

Electric voltage |

220V±10% 50/60HZ |

|

Total Power |

4700W |

|

Printer size(L*W*H) |

4200*3500*1580mm |

|

Printer weight |

3200kgs |